About the Company

Alexander Battery Technologies is a leading designer and manufacturer of custom lithium-ion battery packs. Their modern manufacturing facility focuses on delivering innovative battery solutions to support some of the world’s largest and most demanding OEM businesses. Their values of trust, transparency, and positive energy drive their mission to support cleaner and more renewable energy through advanced battery technology.

Challenges

Staying competitive: as a global battery pack manufacturer, Alexander Battery Technologies is looking to maintain its competitive edge by delivering the best possible value to their customers without compromising on quality. The company required a manufacturing solution that could deliver high-quality precision welds quickly and consistently.

Improving productivity: the company has aggressive short term growth goals and is continuously seeking ways to improve productivity. Meeting and exceeding customer demands in a fast-paced and ever-changing industry can only be accomplished by implementing high-performance equipment and solutions.

Increasing sustainability: like most manufacturers, Alexander Battery Technologies has increased their focus on developing more environmentally friendly processes. With global initiatives requiring businesses to reduce carbon emissions, the company is constantly seeking more sustainable and energy efficient technologies.

The Solution

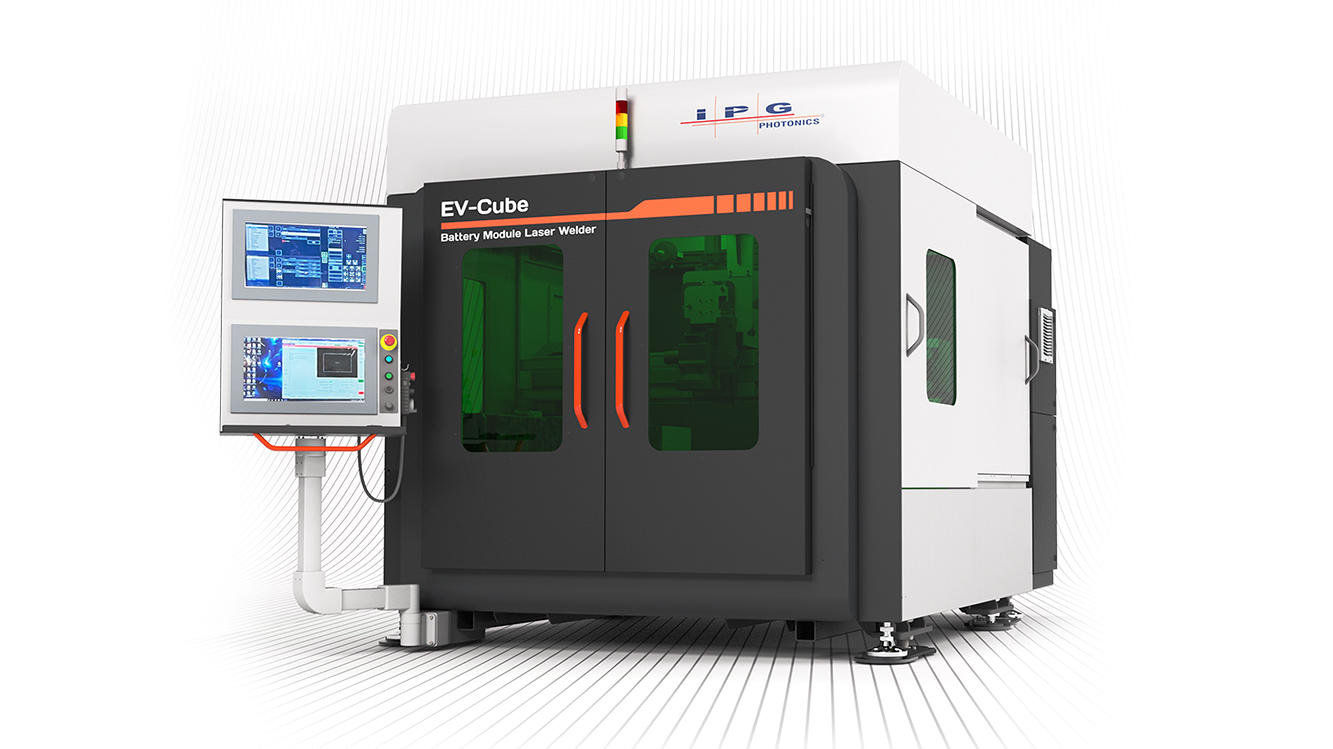

It was already clear to The Alexander Battery Technologies engineering team that introducing laser welding to their facility was critical. The team had interacted with IPG numerous times through online content and industry events and began considering the EV-Flex Battery Welding System. Members of the engineering and production teams reached out to IPG to learn more before ultimately visiting IPG’s Allershausen, Germany location to perform factory acceptance tests.

As a fully automated workstation for welding busbars for battery modules, the EV-Flex laser welding system is purpose-built for manufacturers like Alexander Battery Technologies. The system accommodates modules up to 1200 x 1000 x 300 mm, enabling the company to produce a variety of battery types including high-voltage assemblies containing hundreds of cells.

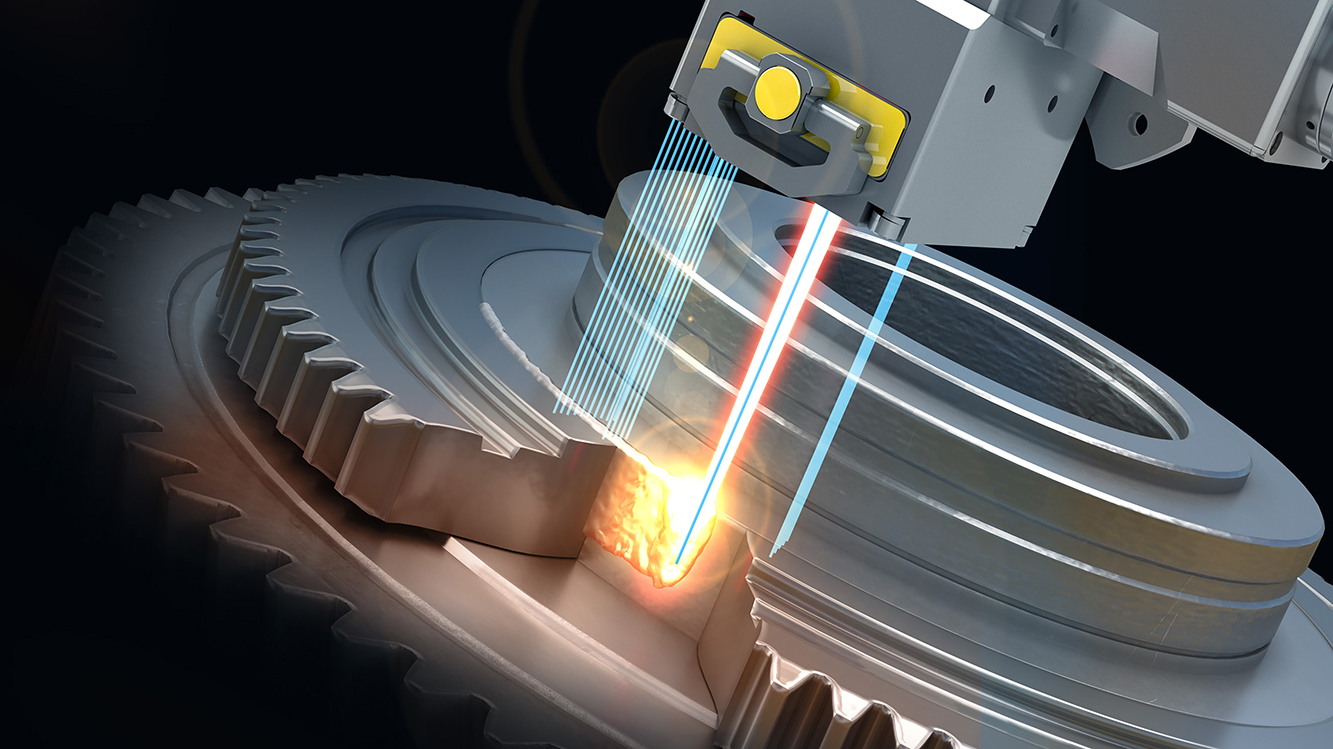

The EV-Flex that was installed in Alexander Battery Technologies’ facility in May 2024 was fitted with technologies that supported the company’s focus on increasing productivity and ensuring consistently high-quality welds. The use of an Adjustable Mode Beam (AMB) dual-beam laser enables high-speed welding while virtually eliminating unacceptable weld defects like spatter and porosity. By employing LDD real-time laser weld measurement technology, the company is now able to accurately measure every weld as it is made to ensure the safety and performance of the final product.

Working with IPG

IPG is more than just a laser company – we are a global laser solutions provider and single vendor source for everything from industry-leading laser technology to custom laser systems. At IPG we combine laser expertise with industry know-how to offer solutions that maximize the power of laser processing, minimize risk, and enable sustainable manufacturing.

Are you considering a laser processing solution? Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.

Get Started