- Home

- Products

- Laser Systems

- Modular Laser Curing System

Modular Laser Curing System

High-Speed Laser Powder Coat Curing

~2 Minute

Curing Time

± 1° C

Heat Control

4X

Smaller Footprint

A flexible design combined with the speed and efficiency of laser curing empowers manufacturers to dramatically reduce curing costs while maximizing throughput and minimizing environmental impact.

~2 Minute

Curing Time

± 1° C

Heat Control

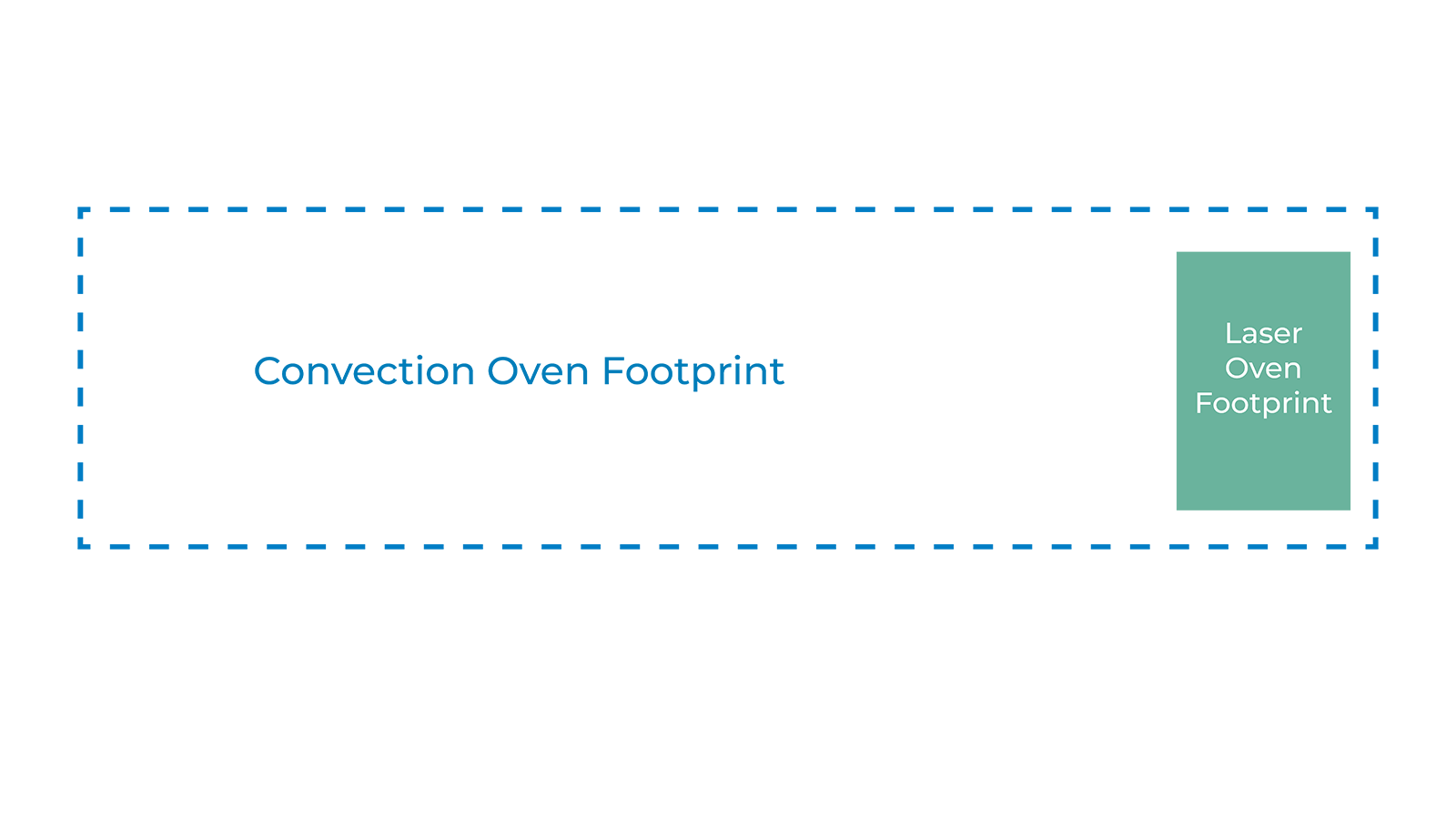

4X

Smaller Footprint

A flexible design combined with the speed and efficiency of laser curing empowers manufacturers to dramatically reduce curing costs while maximizing throughput and minimizing environmental impact.

Why Laser Powder Coat Curing?

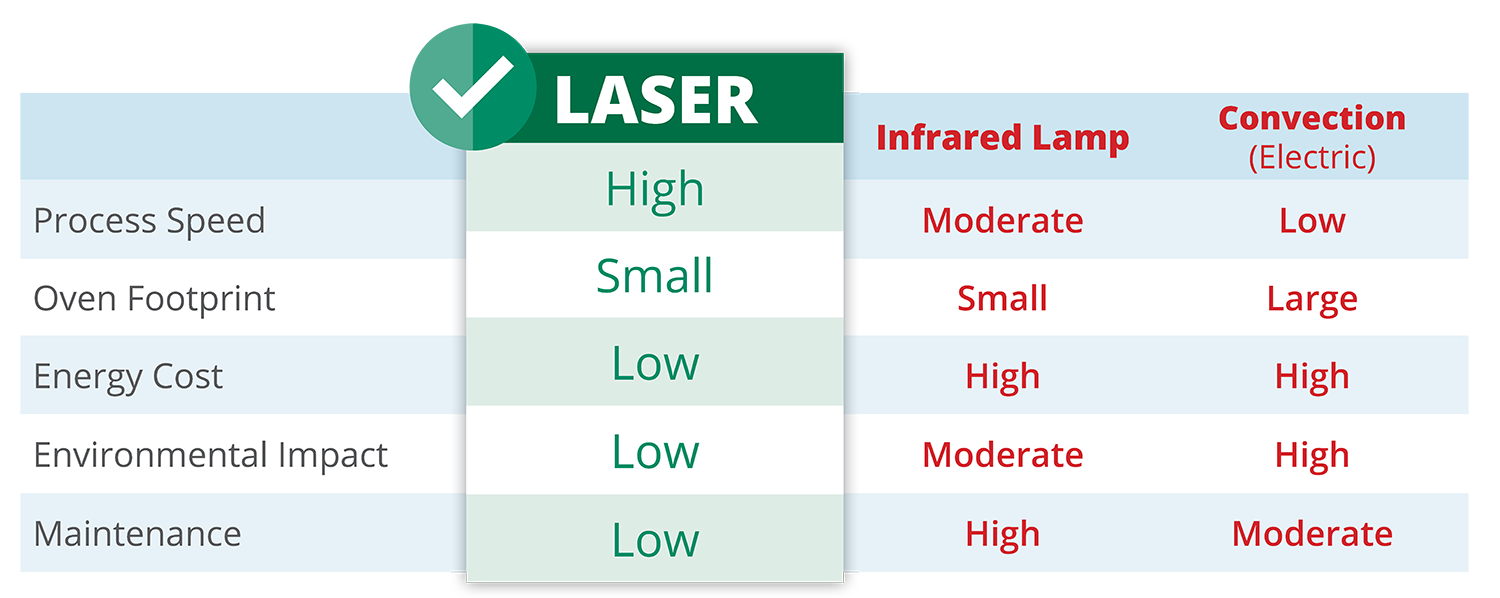

Laser Curing vs. Alternative Curing Methods

Up to 10X Faster Than Convection

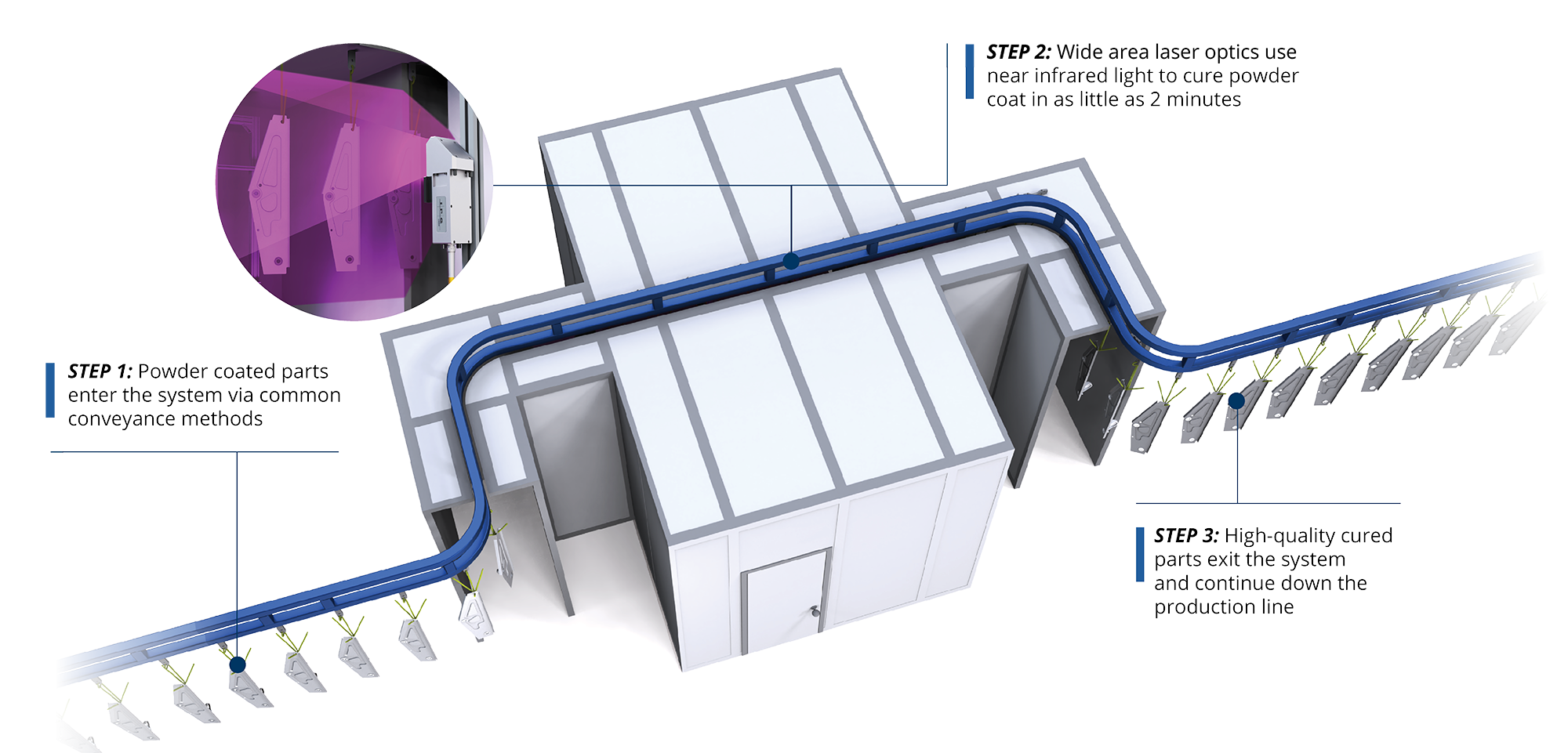

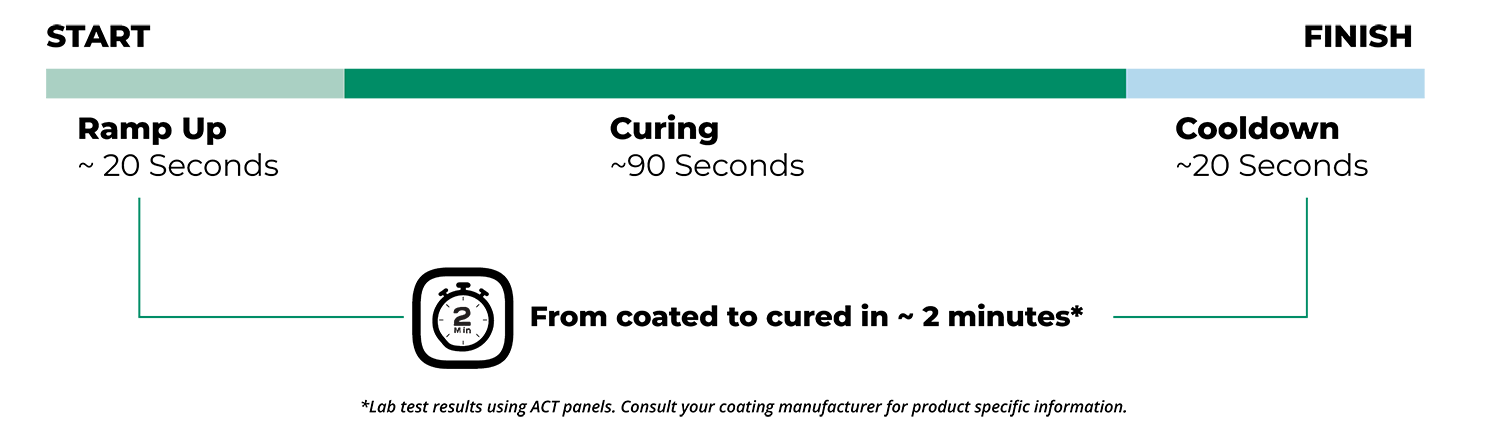

The moment a laser oven is turned on laser energy immediately penetrates the powder surface, heating the coating in volumetric fashion.

Laser curing achieves a powder-to-liquid phase transition in seconds before rapidly completing the curing process. The high curing speed reduces unnecessary heating of the part, minimizing cooling times.

Unmatched End to End Efficiency

Ultra-Efficient Laser Technology

IPG laser technology provides the highest electricity to heating efficiency available.

Precision Energy Direction

Laser curing targets a controlled area, wasting no energy heating the rest of the oven.

No Pre-Heating or Idling

Near instant starting and stopping means laser power is only on when curing is underway.

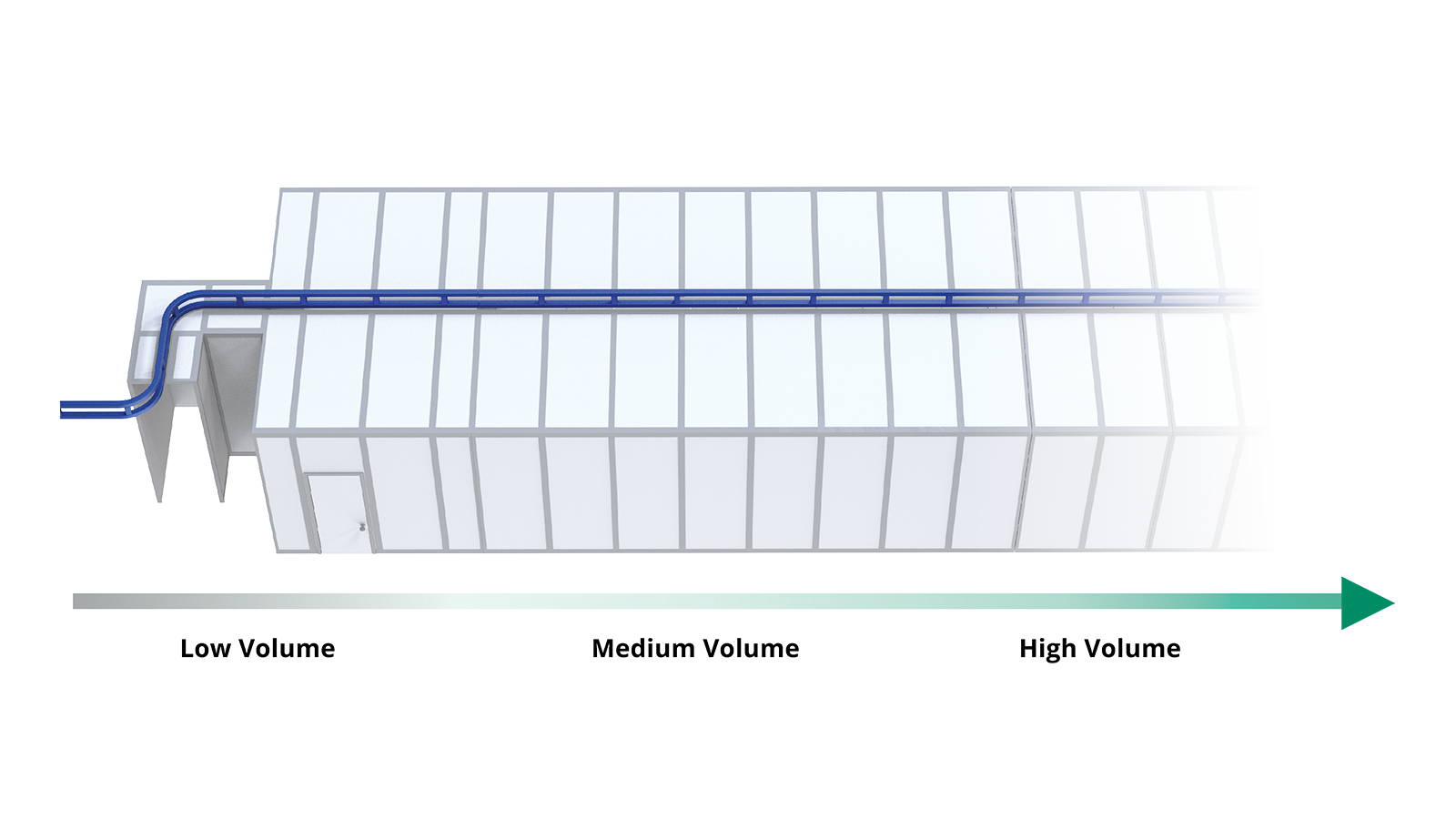

Dramatically Reduced Space Requirements

The incredible speed of the laser curing process means that powder coated parts spend less time being cured. Faster curing times translate directly to reduced oven length requirements.

As a result, laser ovens match the productivity of convection ovens with 10% of the floorspace.

System Features & Configurations

Right Sized for Your Operation

From 8 feet to 100, a modular cell design means the length of your laser oven always matches your exact space and throughput requirements, even as your operation grows.

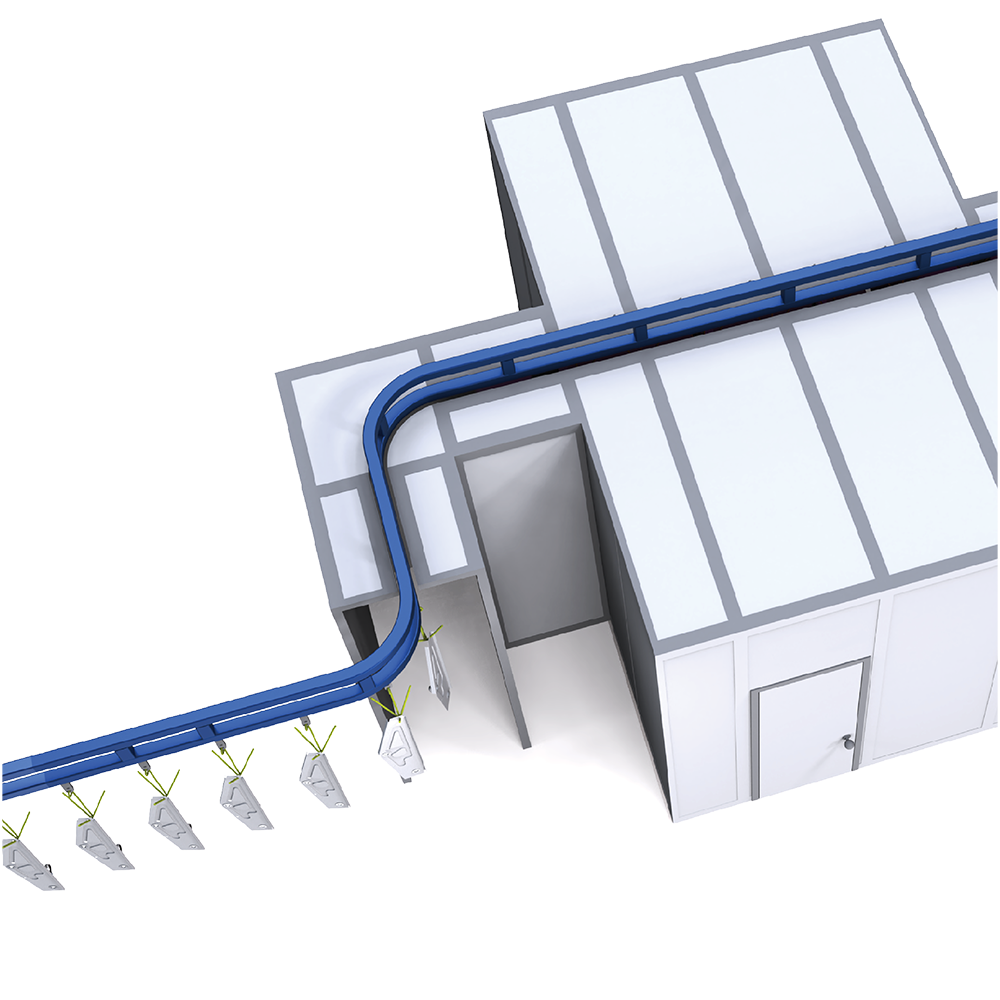

Seamless Integration with Common Conveyors

Continuous Conveyance

A laser safe "light labyrinth" option traps light, allowing for continuous conveyance.

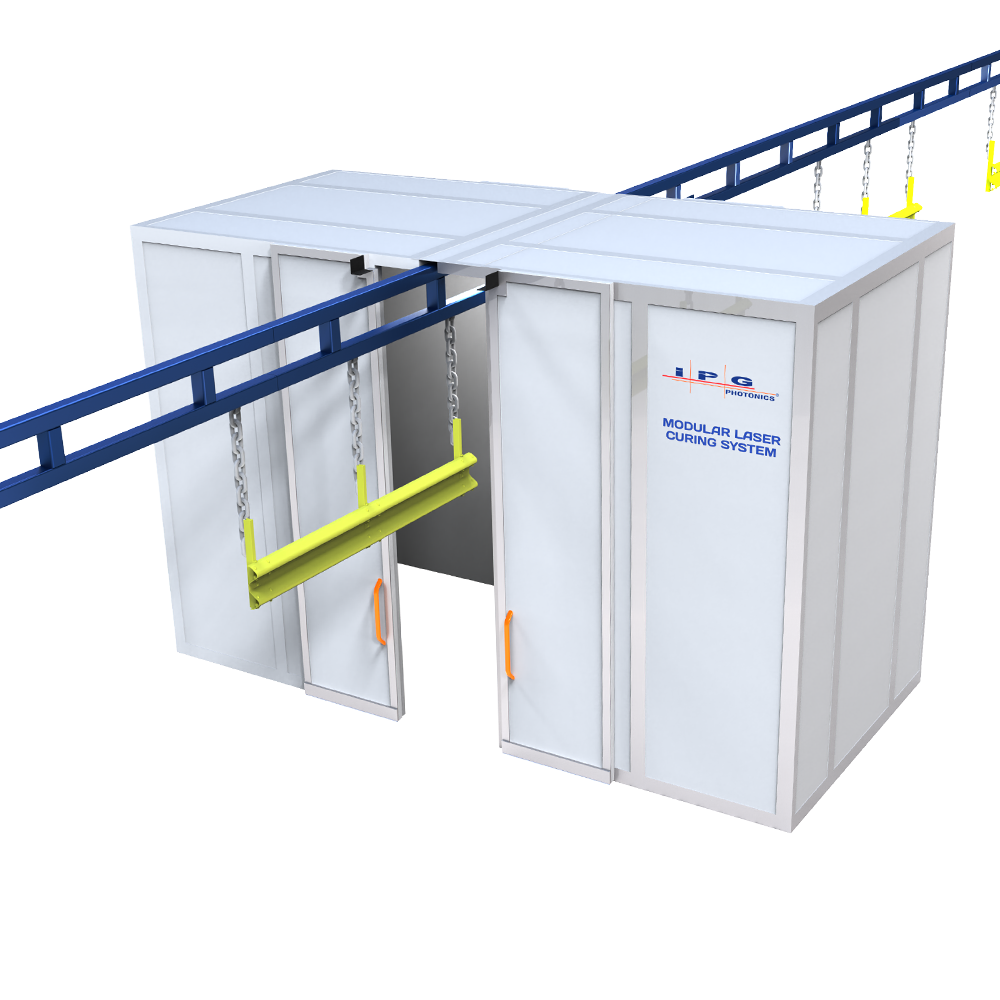

Stop-And-Go Conveyance

Choose between automatic or manual doors for a light-tight enclosure that integrates with stop-and-go conveyance.

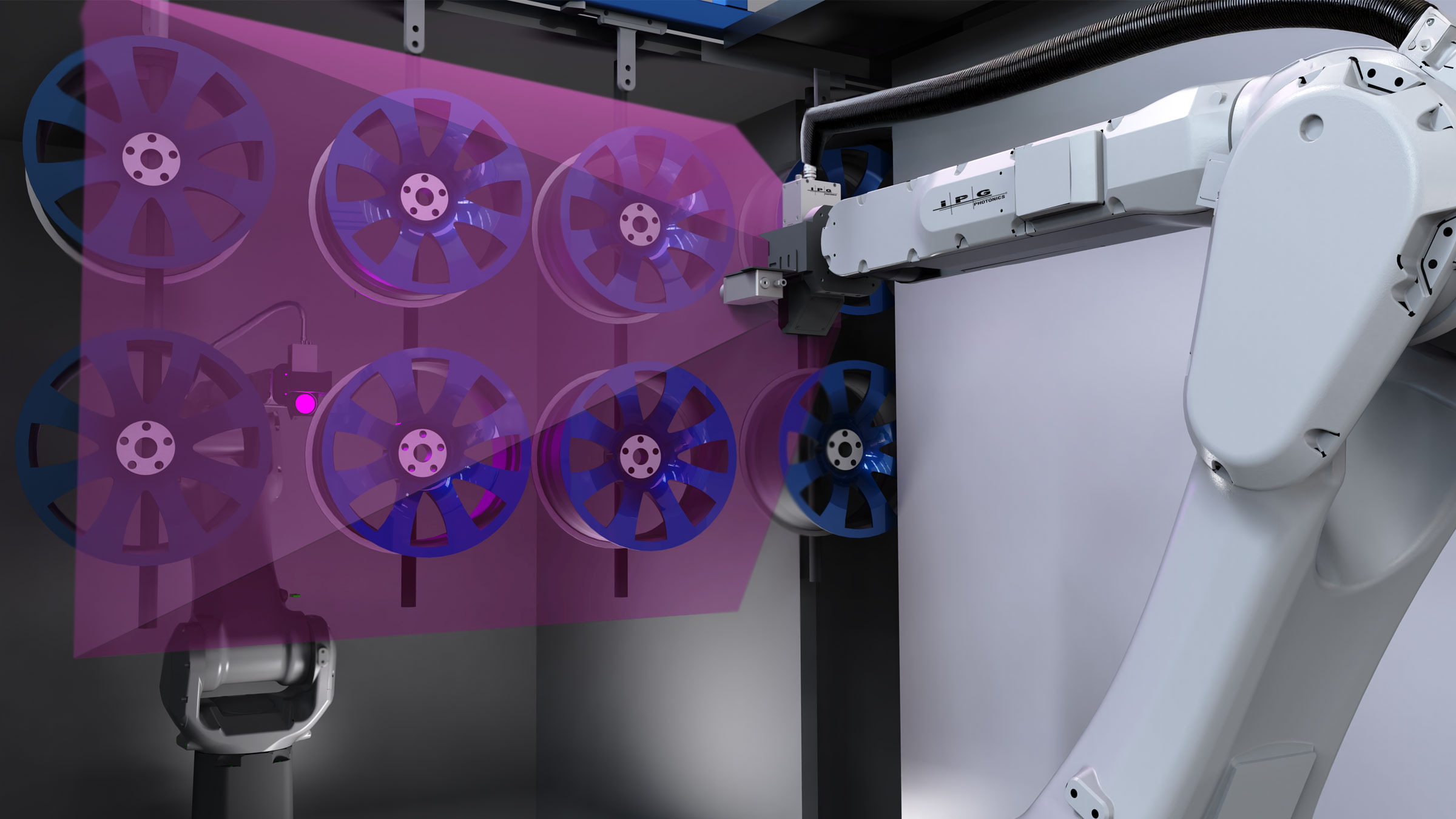

Optimized Beam Delivery for Any Part Mix

From manually adjustable optics to 3-axis and robotic options, the Modular Laser Curing System delivers consistent curing quality no matter your part mix or part complexity.

Unprecedented Temperature Monitoring & Control

The Modular Laser Curing System can be equipped with a variety of internal temperature sensors. Not possible with traditional convective and infrared curing methods, in-situ temperature measurement and adjustment enable the curing process to be more precise than ever.

IR Thermal Sensor

Ideal for most full-production curing processes, small spot thermal sensing delivers data to system software for precise control over process temperatures.

FLIR Thermal Camera

Providing a full thermal view of the entire part, precision thermal cameras provide detailed data and enhance the temperature control loop.

High-Precision Pyrometer

By collecting high-resolution data, an internal pyrometer sensor enables in-house R&D and process development.

Modular Laser Curing System Specifications

|

| Modular Laser Curing System |

| System Characteristics |

|---|

| Modular Cell Dimensions |

| Length Minimum: 2.4 m Maximum: Unlimited (Increments of 1.2 m) Height up to 5 m Depth Customer Part Dependent |

| Laser Safety |

| Class I Laser Enclosure Laser Safe "Light Labyrinth" or Manual/Automatic Doors |

| Curing Speed |

| ~2 minutes |

| Laser & Beam Delivery |

| Laser Source |

| IPG DLS Series Laser (from 4.5 kW to 100 kW) |

| Beam Delivery Optics |

| IPG DLS Wide Area Projection Head |

| Projection Head Mounting Options |

| Fixed Manually Adjustable (XYZ) Penumatic (XYZ) Servo (XYZ) Robotic (6-axis) |

| Control & Monitoring |

| Software |

| IPG DLS/HMI Software |

| Temperature Control Options |

| Infrared Temperature Sensor FLIR Thermal Camera Precision Pyrometer Sensor |

| Safety |

| Optional Human Detection Safety Radar |

| Learn More |

|

|||

| System Characteristics | |||

| Modular Cell Dimensions | Length Minimum: 2.4 m Maximum: Unlimited (Increments of 1.2 m) Height up to 5 m Depth Customer Part Dependent | ||

| Laser Safety | Class I Laser Enclosure Laser Safe "Light Labyrinth" or Manual/Automatic Doors | ||

| Curing Speed | ~2 minutes | ||

| Laser & Beam Delivery | |||

| Laser Source | IPG DLS Series Laser (from 4.5 kW to 100 kW) | ||

| Beam Delivery Optics | IPG DLS Wide Area Projection Head | ||

| Projection Head Mounting Options | Fixed Manually Adjustable (XYZ) Penumatic (XYZ) Servo (XYZ) Robotic (6-axis) | ||

| Control & Monitoring | |||

| Software | IPG DLS/HMI Software | ||

| Temperature Control Options | Infrared Temperature Sensor FLIR Thermal Camera Precision Pyrometer Sensor | ||

| Safety | Optional Human Detection Safety Radar | ||

| Learn More |

The specifications above represent standard system configurations. IPG can offer customized specifications upon request.

Product availability may vary by region.