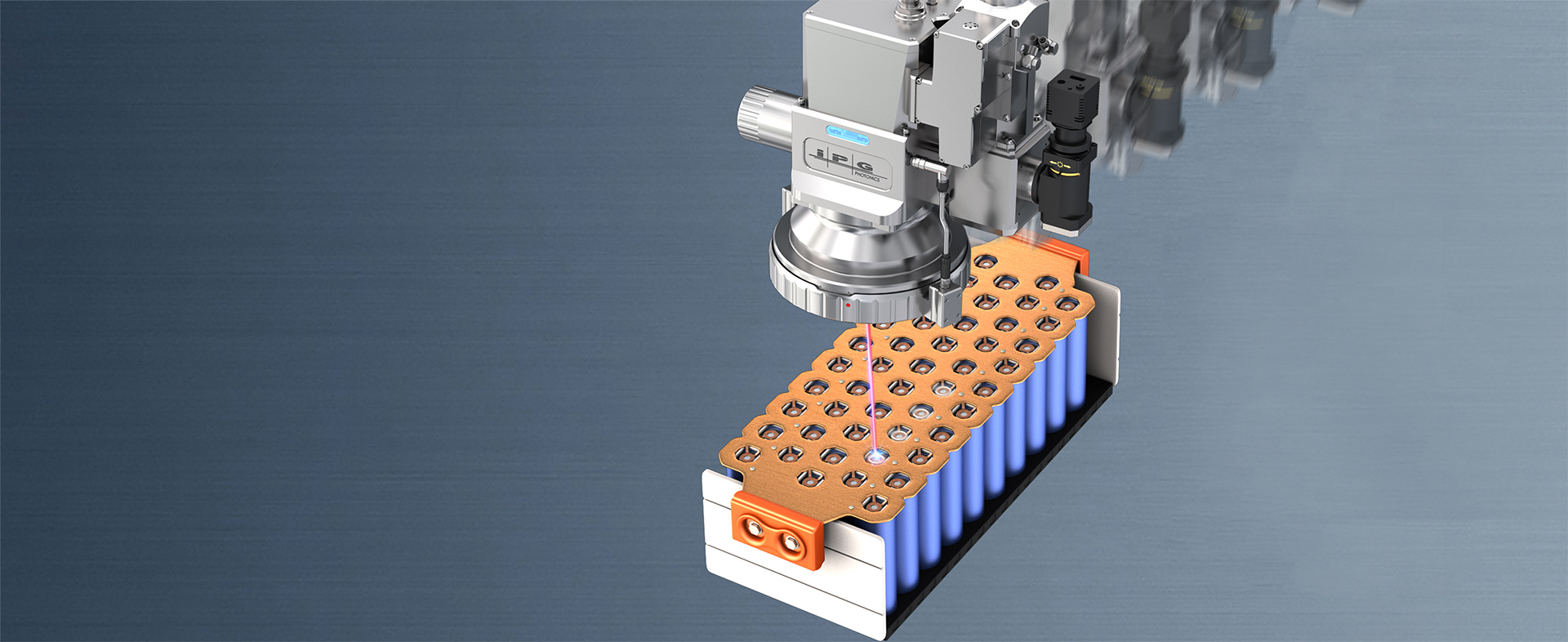

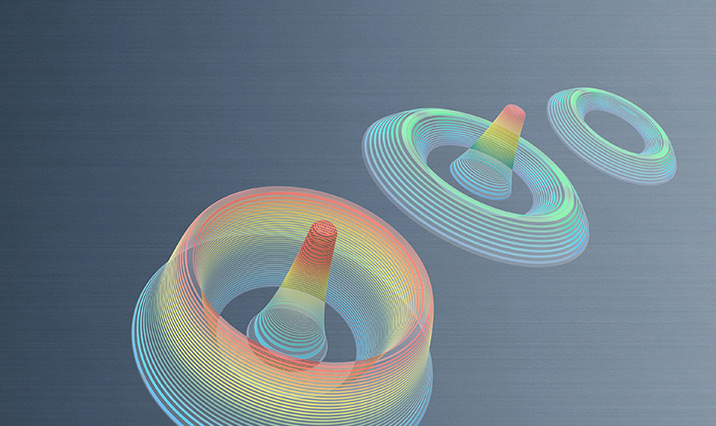

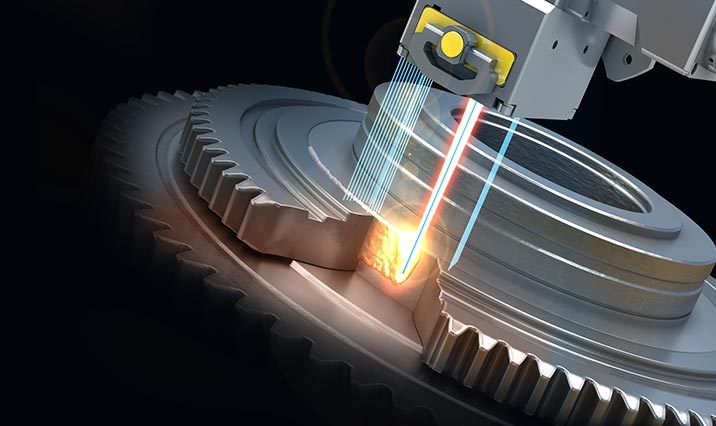

On-the-fly (OTF) welding, also known as welding on-the-fly, is an automated laser welding process characterized by continuous motion. An advanced form of scanner welding, this laser welding technique utilizes scanning optics and real-time calculations to account for system motion while ensuring the beam is still directed precisely. Welding while either scanning optics or the target workpiece remain in motion enables a dramatic increase in welding throughput.

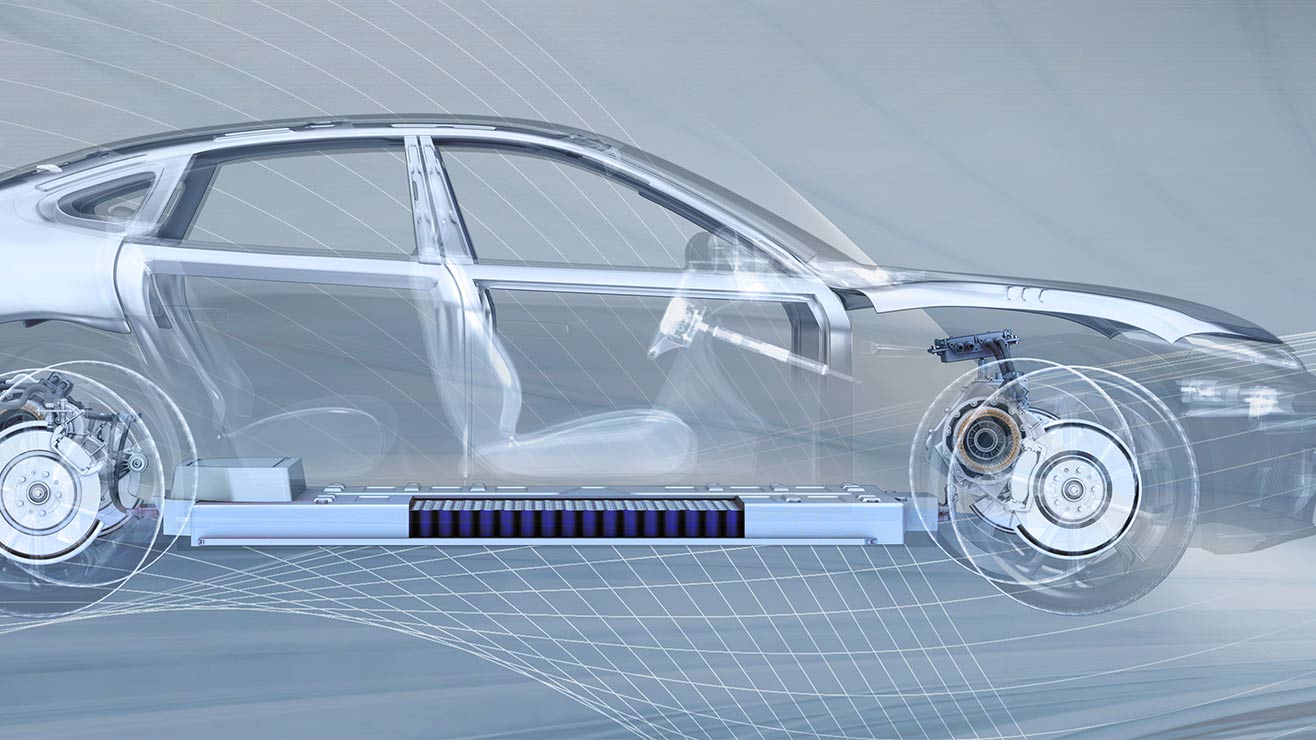

Traditional laser welding methods, while often faster than non-laser welding, must come to a stop periodically to make welds. This is true even in the case of traditional scanner welding approaches. By greatly reducing process stops and starts, on-the-fly welding is a powerful technology for maximizing manufacturer productivity when producing both high volumes of small parts and large parts with many individual welds.