- Home

- Products

- Laser-Systems

- Lasercube-Cutting

LaserCube Cutting System

Small Parts Made Easy

Up to 6 kW

Laser Power

±25 μm

Accuracy

1000 mm / sec

Maximum Speed

A combination of unmatched IPG laser capabilities and quality system components enables quality cutting edges and high productivity in a wide range of materials and thicknesses from thin foils to half inch thick steel.

Up to 6 kW

Laser Power

±25 μm

Accuracy

1000 mm / sec

Maximum Speed

A combination of unmatched IPG laser capabilities and quality system components enables quality cutting edges and high productivity in a wide range of materials and thicknesses from thin foils to half inch thick steel.

A Flexible Precision Cutting Workstation

Powered by the Best Lasers Available

HIGH-SPEED CUTTING: Excellent beam quality and a high peak power option enable the highest cutting speeds, even in reflective metals.

ZERO-MAINTENANCE: No gases to replace, no mirrors to align, no consumables, and no downtime.

UNPARALLELED RELIABILITY: The legendary power stability of IPG lasers provides long-term and reliable laser processing quality.

Small Footprint

With a modest requirement of just 5.7 square meters, the LaserCube laser cutting system optimizes space utilization without compromising on performance.

IPG fiber lasers up to 6 kW can be mounted within the workstation cabinet, further contributing to the compact design.

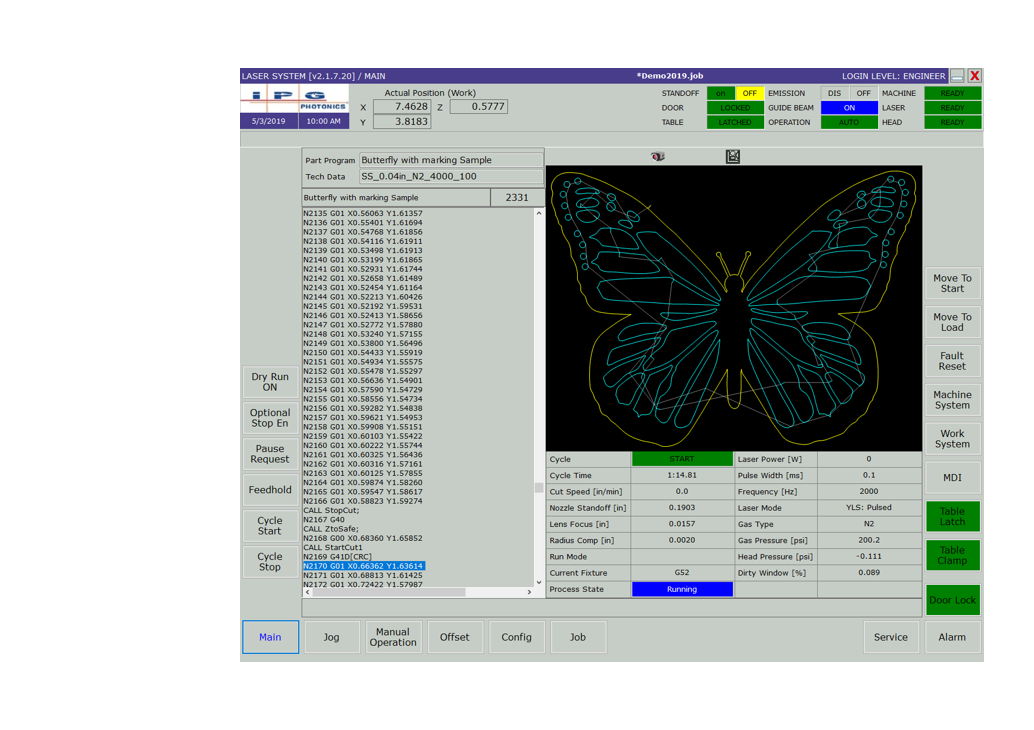

Easy-to-Use Software

IPG software is preloaded and tested at IPG prior to shipment and provides the use with a comprehensive, easy-to-use programming and operator interface.

- Fully integrated control of laser, system motion, beam delivery, process control, and vision

- Live G/M code display with production controls for interrupt and resume

- Stored and editable library of cutting parameter tables for a wide variety of materials

- On-machine part nesting for arrayed parts

Vision Registration for Repeatable Cut Placement

The LaserCube can be equipped with an optional vision system that positions cuts where they belong even when part and feature placement vary.

- Ideal for cutting pre-processed materials such as screen-printed plates, punched parts, or chemically etched components

- Automatically accounts for the effects of dimensional deviations or operator error, reducing process requirements prior to laser cutting

- Laser-punch combo capability when used with an existing punch press

Discover Your Next Laser Solution

Our application engineers, developers, and scientists are available across dozens of global state-of-the-art IPG application centers to help with everything from process development and optimization to full scale production.

Getting started is easy — send us a sample for evaluation or just tell us about your project and we'll take it from there.

LaserCube System Specifications

|

| LaserCube Laser Cutting System |

| Maximum Cutting Speed |

|---|

| 1000 mm/s |

| Materials |

| Stainless/Mild Steel, Aluminum, Brass, Copper, Laminated Foils |

| XYZ Working Range |

| 1250 x 1250 x 75 mm Optional Rotary for Tube Cutting |

| Positioning Accuracy |

| ±25 μm |

| Positioning Repeatability |

| <10 μm |

| Material Loading |

| Telescoping Drawer with Metal Cutting Bed Optional External Pallet Support for Heavy Sheets Optional Automated Material Loading |

| Part Tooling |

| Manual Clamping Optional Pneumatic Clamping |

| Control Software |

| CNC G-code Compliant HMI |

| Display & Operation |

| 17" Monitor with Keyboard & Mouse |

| Safety & Compliance |

| Class 1 Laser Safe CE Certified |

| Laser & Beam Delivery |

| IPG Laser Source |

| Selected to Best Match Application |

| Laser Integration |

| Internal or External |

| Beam Delivery Head |

| IPG Cutting Head |

| Learn More |

|

|||

| Maximum Cutting Speed | 1000 mm/s | ||

| Materials | Stainless/Mild Steel, Aluminum, Brass, Copper, Laminated Foils | ||

| XYZ Working Range | 1250 x 1250 x 75 mm Optional Rotary for Tube Cutting | ||

| Positioning Accuracy | ±25 μm | ||

| Positioning Repeatability | <10 μm | ||

| Material Loading | Telescoping Drawer with Metal Cutting Bed Optional External Pallet Support for Heavy Sheets Optional Automated Material Loading | ||

| Part Tooling | Manual Clamping Optional Pneumatic Clamping | ||

| Control Software | CNC G-code Compliant HMI | ||

| Display & Operation | 17" Monitor with Keyboard & Mouse | ||

| Safety & Compliance | Class 1 Laser Safe CE Certified | ||

| Laser & Beam Delivery | |||

| IPG Laser Source | Selected to Best Match Application | ||

| Laser Integration | Internal or External | ||

| Beam Delivery Head | IPG Cutting Head | ||

| Learn More |

The specifications above represent standard system specifications. IPG can offer systems with customized specifications upon request.

Product availability may vary by region.