Keeping things clean is essential for industrial food processing facilities. Contaminants like oil, grease, dust, and food residue can impact batch quality or even cause serious hygienic problems.

Traditionally, industrial food equipment has been cleaned, whether in-place, out-of-place, or manually, using a variety of detergents and other cleaning chemicals. Abrasive methods like sandblasting are also used, although less frequently.

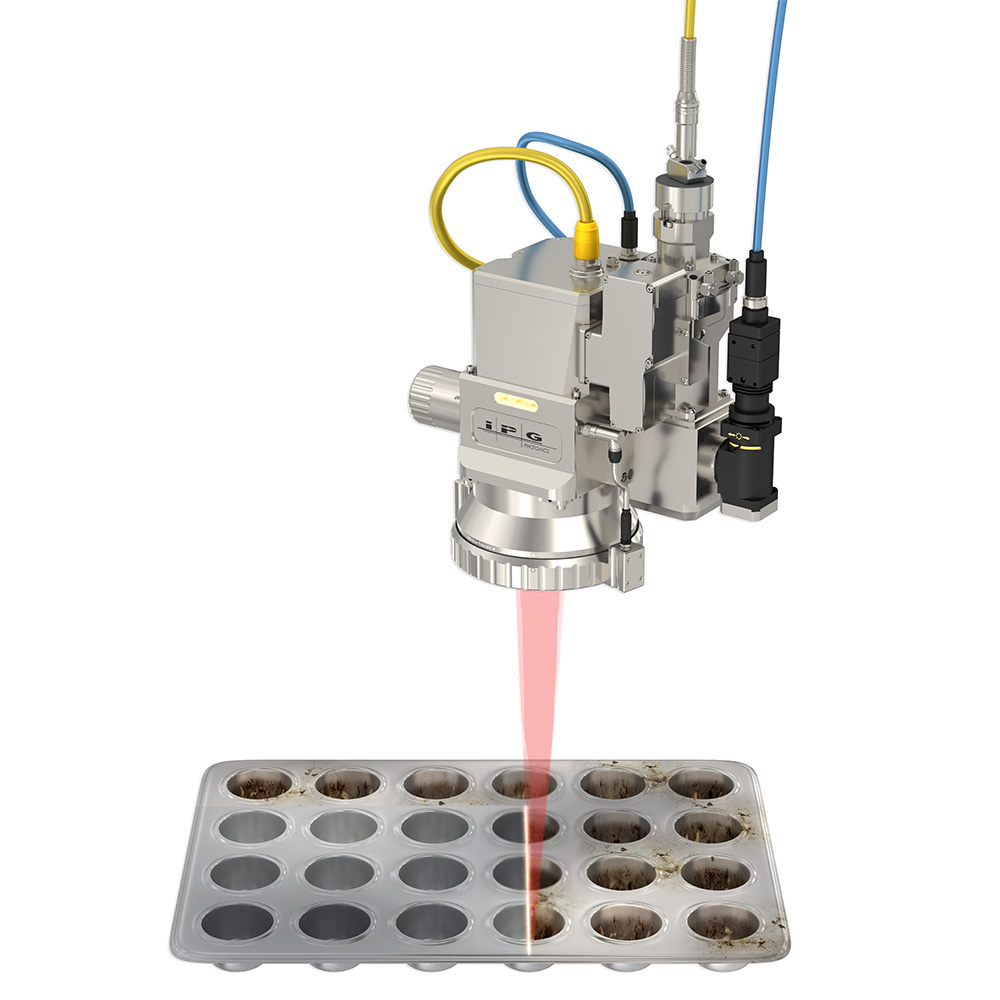

As industrial laser tools continue to be successfully deployed across applications and industries, laser cleaning has experienced a surge in popularity. With a proven track record in aerospace and general fabrication, laser cleaning has demonstrated a variety of compelling advantages, drawing attention from the food processing industry as well.

This article will cover the basics of laser cleaning and the benefits it offers the food processing industry.

What is Laser Cleaning?

Laser cleaning, also known as laser material removal and laser ablation, is a method of eliminating thin layers of material from a target surface. This is typically accomplished by rapidly scanning a pulsed laser beam across the material in one or more passes. The highly focused energy delivered by the laser beam induces thermal shock to peel off, vaporize, sublimate, or burn away unwanted material with virtually no impact to the material underneath.

Advantages of Laser Cleaning for the Food Industry

Cleaning Speed

Laser cleaning is an exceptionally high-speed process. Depending on the material to be removed and the level of automation, lasers can clean more than 1,000 square meters of surface area per hour.

Cleaning Precision

Laser cleaning removes surface contaminants with virtually no impact to the material underneath, leaving the final product with a shiny, never-used appearance. The process also sanitizes target surfaces, making them clean enough to eat from.

Abrasive cleaning methods, by comparison, steadily wear down equipment like baking trays and molds, deforming the shape and reducing material thickness. Laser cleaning also minimizes heat impact to the equipment compared to oven-based cleaning methods that can cause thermal deformation.

Selective Cleaning

Laser cleaning can target virtually any surface shape or size on food processing equipment with near-perfect accuracy.

Cleaning Safety

Although handheld laser cleaning equipment requires additional safety considerations, enclosed laser cleaning systems are very safe. Laser cleaning also reduces worker exposure to cleaning chemicals as well as the noise and dust introduced by abrasive methods like sandblasting.

Environmentally Friendly

Industrial fiber laser systems are highly energy efficient. Additionally, laser cleaning dramatically reduces the material and waste handling requirements associated with transporting and disposing of physical cleaning media. Typically, a laser cleaning solution requires nothing more than a fume extraction system.

Automation

Although laser cleaning can be a manual process using handheld devices, laser cleaning is well-suited for automation. Laser cleaning systems can be manually loaded as workstations or serve as robotic conveyor-fed cells. Equipment like conveyor belts, bands, or even baking molds and pans can be cleaned within the production flow rather than being accumulated and batch cleaned.

Flexibility

Lasers are capable of cleaning a variety of materials, including rust, coatings, oil, dust, and more. For food processing, laser cleaning can address virtually all food deposits including grease, charred material, and baked-on food soils whether they are fat-based, protein-based, carbohydrate-based, or mineral-salt-based. Unlike cleaning chemicals, laser light is not concerned with water, alkali, or acid solubility, although parameters may need to be adjusted to achieve optimal performance in different applications.

What Food Processing Equipment Can Lasers Clean?

Baking Equipment: Laser cleaning is well-suited for cleaning baking trays, molds, pans, and ovens.

Frying Equipment: Whether targeting oil, grease, or other food residue, laser cleaning can clean various features and surfaces of industrial deep fryers and frying equipment.

General Food Equipment: Laser cleaning offers the flexibility to deep clean equipment like conveyor belts and industrial mixers as well as filling and extruding equipment.

Getting Started with Laser Drilling for Filter Production

If you are considering laser cleaning for a food processing application, IPG can help. Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.