Industrial lasers have experienced adoption across many industries, where they continue to replace traditional manufacturing tools and methods by offering increased throughput, flexibility, and precision.

For many manufacturers, lasers have become a mainstay for applications like cutting, welding, and marking. But some manufacturers have begun to take advantage of lasers for demanding drilling applications as well. The aerospace industry, for example, recognized years ago the advantages of laser drilling for creating precision holes in engine components to aid in cooling, improve fuel efficiency, and reduce drag.

Continuous advances in laser drilling technology have also presented opportunities for the filter manufacturing industry. This article will cover the basics of laser drilling and the benefits it offers to industrial filter and screen manufacturers.

What is Laser Drilling?

Laser drilling is a non-contact holemaking process that uses a highly focused beam of light to drill or punch holes. Laser drilling shares many similarities with laser cutting, as both are concerned with achieving full penetration of the target material. However, laser drilling is typically used to create small holes that rely on minimal or no lateral cutting motions.

Filter Design & Requirements

Filters play a critical role in industries such as food processing, industrial recycling, water treatment, and air filtration, where they are used to separate a wide variety of materials. The exact requirements of a filter depend on the size of the particles being filtered.

For example, industrial plastic recycling operations often rely on filters to allow low-temperature molten plastic to flow through expanding holes while trapping solids at the hole entrance. In this case, hole shape and size are crucial to promoting smoother plastic flow and reducing debris buildup.

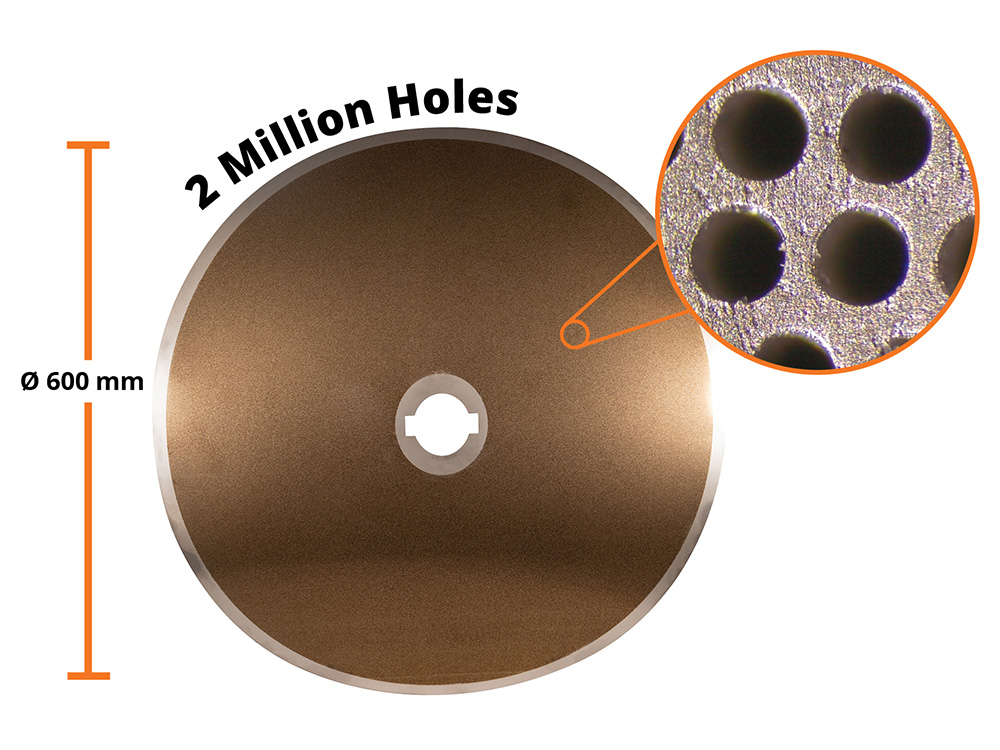

An example of a laser drilled high-density filter used for plastic recycling. Filter Diameter: 600 mm. Thickness: 1 mm. Material: 316L Stainless Steel. Hole Quantity: 2,000,000. Drill Rate: 100 holes/second. Equipment: LaserCube Driller Flat Sheet Laser Drilling System.

Hole distribution also plays a large role in filter performance. While hole size is governed by what needs to be filtered, filtering speed can potentially be increased by increasing the number of holes. At the same time, the filter must be able to withstand filtering back pressures. Although the size of individual filters varies widely by application and industry, filters often require thousands or even millions of holes.

Advantages of Laser Drilling for Filter Production

Cost Efficiency

Once equipment is purchased, laser drilling is a low maintenance and energy efficient method of producing filters. Filter end users, who often purchase expensive replacements from filter providers, sometimes opt instead to fabricate their own replacements.

For larger operations, particularly plastic recyclers, the savings afforded by bringing filter manufacturing in house can exceed the initial cost of laser drilling equipment within months.

Speed

Although laser drilling systems drill a single hole at a time, on-the-fly drilling can be used to create dozens, hundreds, or thousands of holes per second depending on the thickness of the target material.

Hole Size

Filters often require exceptionally small holes with diameters as small as 60 microns. Contact tools like drills and punches are not feasible for creating high volumes of ultra-small holes at scale. These sizes are best achieved with laser drilling or electron beam machining. However, electron beam machines are expensive and vacuum requirements typically limit overall filter size.

Hole Pitch

High-density refers to the relative distribution of filter holes, or pitch, measured center-to-center from one hole to another. Although it is difficult to quantify what constitutes a “high” hole density, high-density filters are often designed with pitches 2 to 5 times the hole diameter. This is difficult to achieve with non-laser methods.

Hole Shape & Taper

Many filters benefit from conical holes that taper from a smaller hole on the “entrance” side to a larger hole on the “exit” side. Laser parameters can be easily adjusted to produce filter holes with the desired taper.

Precision & Accuracy

Laser processing is highly accurate and precise and laser drilling is no exception. Laser drilling can maintain highly consistent shape holes and sizes while also placing holes very accurately. As a non-contact process, laser drilling also suffers from no tool wear and thus virtually no degradation over time.

Hole Shape

Laser drilling is capable of creating holes of nearly any shape, although filters are commonly designed with circular, hexagonal, or square holes.

Getting Started with Laser Drilling for Filter Production

If you are considering laser drilling for manufacturing filters, screens, sieves or other holemaking applications, IPG can help. Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.