What is Laser Cleaning?

Laser cleaning, a form of laser ablation, is a method of removing a selective layer of material from a surface using laser energy. The laser cleaning process utilizes photonic energy to peel off, vaporize, sublimate, or burn away unwanted waste material without causing harm to the underlying bulk material.

In most laser materials processing applications, a focused beam forms a relatively small spot on the target material. Laser cleaning is no exception despite typically being used over a relatively wide area. Laser cleaning uses a technique known as laser scanning, which rapidly directs or “scans” a laser beam along a path or across a wider zone. This means that the laser only interacts with targeted material for a fraction of a second at a time.

How Does Laser Cleaning Work?

The goal of laser cleaning is to remove surface material without damaging the material underneath. While lasers can cut through several inches of steel, cleaning requires a significantly lighter touch and an understanding of ablation thresholds. Every material has an ablation threshold that effectively defines the energy required to vaporize it. Stay below the threshold and the bulk material won’t be damaged. Exceed the threshold even once, however, and the bulk material will be impacted.

Fortunately, the materials most manufacturers seek to remove, such as rust, oil, and coatings, have lower ablation thresholds than metals like steel and aluminum. Still, avoiding damage to the substrate requires careful tuning of laser parameters like wavelength and pulse energy. Precise control over spot size and shape also helps make laser cleaning more efficient by minimizing overlap as the beam is scanned.

What Are the Advantages of Laser Cleaning?

Laser cleaning has seen a surge in adoption across a wide range of industries because it offers numerous advantages compared to traditional methods of material removal.

Non-Contact: Laser cleaning is a remote process. In other words, the source of the laser beam operates from several inches or even feet away. This makes the process more flexible and avoids surface damage caused by abrasive methods.

Highly Selective: Lasers are extremely precise and can be fired with virtually perfect accuracy. As a result, lasers only clean the desired area regardless of size or shape. This eliminates additional steps like masking.

High-Speed: Laser cleaning is a high-speed process that can clean up to hundreds of square inches of material per second. Per hour, lasers can clean more than 10,000 square feet of material. Exact material removal rates depend on laser parameters and material properties.

Safe: Laser cleaning has no need for abrasive materials or chemical solvents, reducing noise and eliminating exposure to dust and hazardous materials. Any vapors created during the cleaning process are easily removed with a fume extraction system.

Sustainable: As a media-free process, laser cleaning requires no material handling or disposal. Furthermore, laser systems consume less energy and dramatically reduce the CO2 emissions associated with transport and disposal of cleaning media and chemicals.

Cost-Effective: Requiring minimal material handling, floor space, energy, and maintenance, laser cleaning solutions are long-lasting and exceptionally cost-effective, particularly in the long term.

Laser Cleaning vs. Abrasive Blasting

Abrasive blasting is a common cleaning process that uses high-pressure water or air to propel abrasive particles such as sand, grit, steel shot, or walnut shells. This method can offer acceptable cleaning speeds but requires costly material handling and disposal. Abrasive media can be recycled to offset some costs but reused blasting media experiences degradation that impacts the consistency of cleaning results.

Safety is a major consideration for any abrasive blasting operation. The labor involved in handling abrasive media, including lifting, sweeping, and shoveling it back into hoppers, is both time consuming and physically taxing on workers. Many abrasives generate a high volume of dust, requiring workers to take safety precautions including respiratory equipment and full body PPE. The blasting process is also notoriously loud and poses a serious risk of hearing damage for workers and noise complaints from nearby homes and businesses.

Laser Cleaning vs. Dry Ice Blasting

Also known as cold jetting, dry ice blasting operates similarly to abrasive blasting by using compressed air to propel dry ice pellets. This mitigates some of the problems of abrasive material recovery and disposal due to the dry ice blasting media vaporizing after the cleaning process.

Unfortunately, the use of non-reusable dry ice comes with high consumable costs and is not environmentally friendly. Even with a vapor recovery unit intended to re-pelletize the CO2 gas released by dry ice, the majority of the gas is released into the atmosphere. Like abrasive blasting methods, dry ice blasting is also disruptively loud and requires extra considerations like hearing protection.

Laser Cleaning vs. Chemical Cleaning

Chemical cleaning uses solvents to break down coatings and residues with no damage to the underlying material. This method is typically slow and requires material to both sit in a chemical bath for long periods of time and be dried once cleaning is complete. The lengthy soaking process can be partially overcome by fitting more parts into larger baths but this approach requires a large amount of floorspace.

The hazardous chemicals necessary also require significant safety precautions such as PPE and rigorous disposal procedures. Handling, recycling, and disposal of the necessary chemical solvents has become an increasingly costly challenge due to regulatory controls.

Despite its numerous disadvantages, laser cleaning cannot entirely replace chemical cleaning. While chemical cleaning is not easily applied to a selective area, it is often the only solution for cleaning items with no line of sight such as tubes and complex parts.

Laser Cleaning vs. Thermal Cleaning

Thermal cleaning utilizes very high heats to burn away surface materials. This approach results in high energy costs and can cause damage to the underlying material, depending on the heat tolerance of the surface material and substrate. Thermal cleaning is also inherently incapable of selective removal, even if a mask is used.

How is Laser Cleaning Used?

Laser cleaning is an excellent method for cleaning a wide variety of materials and part types. Laser cleaning is used in a range of applications and at various stages of production, including as a step before or after another process in a production line or for restoration of existing parts. Common laser cleaning applications include:

- Cleaning contaminants like rust, oil, and combustion deposits

- Stripping coatings like paint, e-coat, ceramics, and oxides

- Simplifying mold maintenance by removing release agents and residuals

- Increasing bonding by preparing surfaces for welding, bonding, painting, and coating

- Increasing adhesion with pre-adhesive cleaning or surface texturing

- Increasing coating life by pre-cleaning before applying part coatings

- Sterilizing critical equipment in medical and food applications

What Industries Use Laser Cleaning?

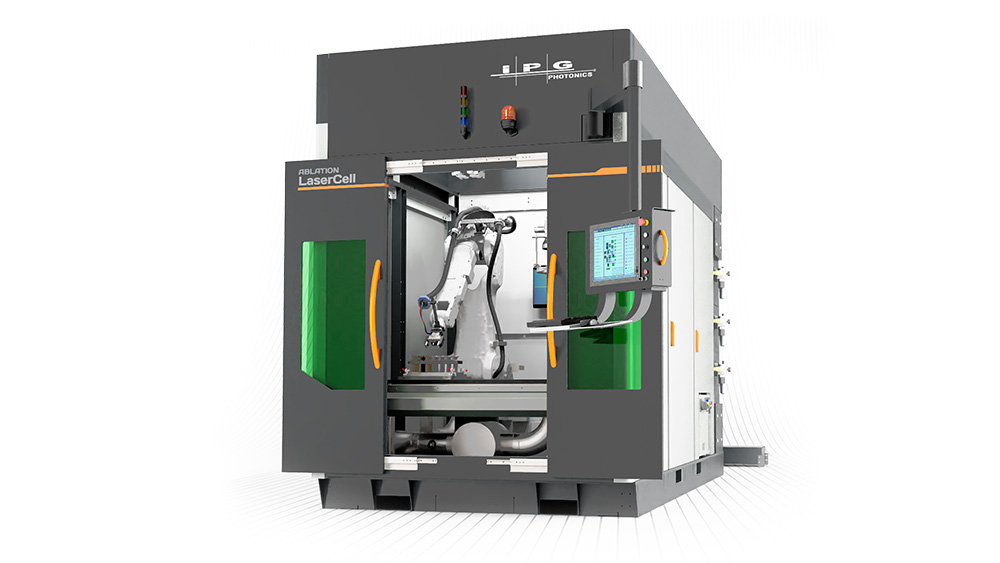

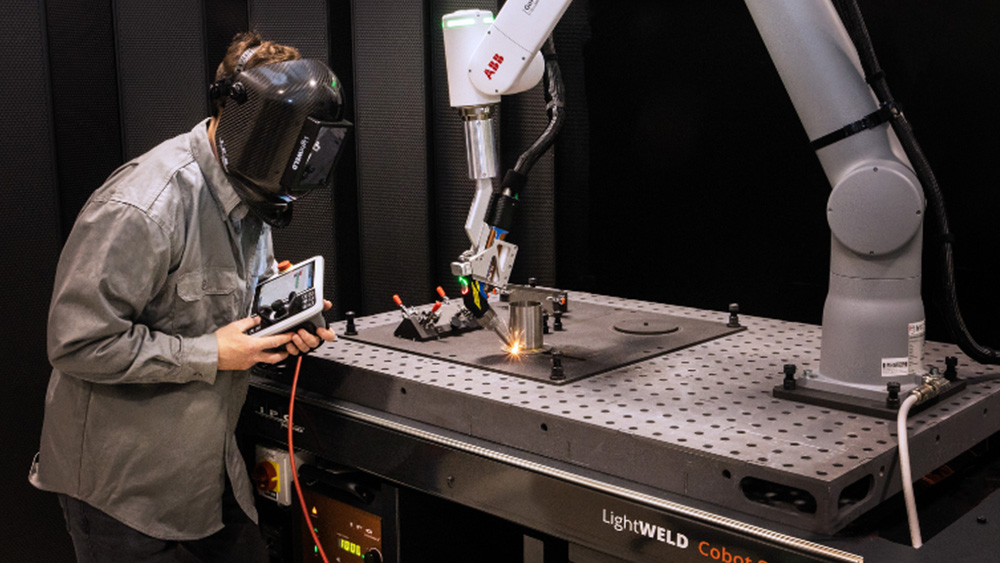

Any industry that must deliver or work with clean surfaces can benefit from the myriad advantages of laser cleaning. As a process, laser cleaning is easily automated and integrated onto the production floor. For smaller scale use, some handheld laser devices offer cleaning capabilities in addition to welding or cutting. Laser cleaning is commonly used in industries such as:

- General manufacturing

- Aerospace manufacturing

- Nuclear decontamination

- Medical device sterilization

- Food and beverage

Getting Started with Laser Cleaning

Many applications and manufacturers can benefit from laser cleaning solutions. From fiber laser sources for cleaning to dedicated laser cleaning systems, an IPG laser cleaning expert is ready to help. Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.